The Corvette Assembly Plant in Bowling Green, Kentucky

If you’ve ever driven thru Bowling Green, Kentucky on I-65, then you almost certainly spotted the Corvette Assembly Plant and the National Corvette Museum on the southbound side of the interstate. For Corvette owners around the world, this mile-long section of Bowling Green, located just south of Exit 28, is known as “Corvette Mecca,” and serves as a destination for Corvette owners, enthusiasts and clubs from across the United States and Canada.

While the National Corvette Museum is often the primary attraction for most visitors, the Corvette Manufacturing Plant (located next door) has also drawn huge crowds over the years. It is a unique destination because it is not an intentional tourist location, but rather a fully functioning vehicle production plant.

The Bowling Green Assembly Plant hosts eight-hundred production workers, represented by the UAW Local 2164. It operates on a single shift, 8-hour, Monday-Friday production schedule. It’s popularity among automotive enthusiasts has grown exponentially over the years because this plant is the only production facility in the world that manufactures the Chevy Corvette.

Where It All Began

General Motors began production of the Corvette at the Bowling Green Plant in 1981, and has been the sole manufacturing facility to build the Corvette since that time. Over the past 37 years, every Corvette ever produced was assembled in Bowling Green and rolled off that production line.

However, Corvette hasn’t always called Kentucky “home”.

In 1953, the first 300 Corvettes ever built were assembled by hand at a facility in Flint, Michigan. The Corvette, a conceptual “dream car” had been introduced earlier that same year at GM’s Motorama Show in New York’s Waldorf Astoria Hotel. The immense popularity of the car and the immediate demand for a production model pushed Chevrolet to begin production before a formal assembly plant could be established.

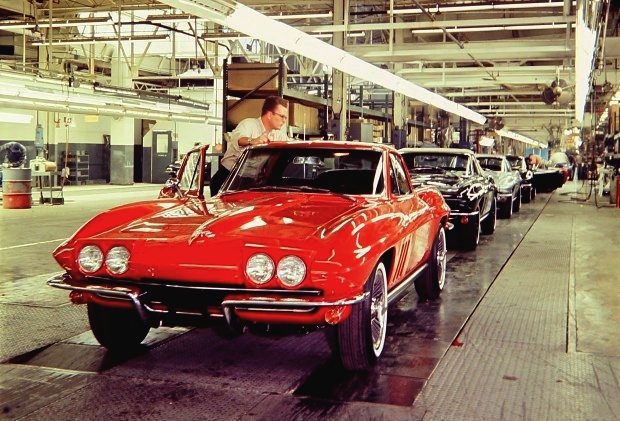

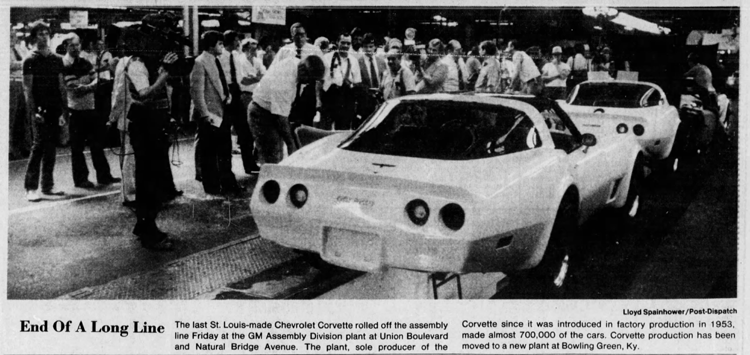

St. Louis, Missouri

The following year, production of the Corvette was moved to St. Louis, Missouri, where it remained for the next 27 years. The plant, which had been built in the 1920’s, was already aging by the time the Corvette took up residence there. By the early-1970s, it was apparent that the aging manufacturing plant would eventually need to be completely overhauled, which meant GM would have to invest a massive amount of money into the plant to keep it on par with its production facilities elsewhere.

While GM considered its options, it also began shopping for alternate locations that could serve as a manufacturing site for the beloved sports car.

In 1979, rumors began circulating that the paint facilities at the St. Louis Plant were obsolete, and in violation of the federal-air-quality standards that had been established by the Environmental Protection Agency (EPA.) That same year, GM admitted that they were considering relocation of their Corvette manufacturing plant to a site that offered a roomier, modernized paint facility.

A New Home?

On March 26, 1979, General Motors officially announced that an impending move was going to occur. General Motors had decided on a facility in Bowling Green, Kentucky which had originally been developed by Chrysler as an automobile air-conditioning unit manufacturing plant.

The site choice was influenced both for its location, which (much like St. Louis) was centrally located in the United States, as well as for significant tax incentives that were offered by the state of Kentucky to bring Corvette production to Bowling Green. GM purchased the property and completely refurbished the site with the intention of using it solely for production of the Y-body Chevy Corvette.

The plant would feature the latest in automobile manufacturing processes, which in turn would ensure a higher level of quality control. The plant would include a state-of-the-art paint shop that would utilize more automated paint processing standards, which in turn would allow Chevrolet to apply more durable enamels to the Corvette. It would also allow them to utilize a more refined clear-coat finishing process.

Construction and renovation of the existing facility was completed in just 14 months, transforming the plant into a modern automotive facility twice the size of the previous structure.

Rumors among Corvette enthusiasts speculated that the relocation of the Corvette plant meant the arrival of the next-generation Corvette. The C3 was more than a decade old already, and the announcements surrounding the major technological advancements that were going to be introduced at the Bowling Green production plant had to mean that a fourth-generation Corvette was imminent!

As it turned out, the speculation was wrong. While Chevrolet had plans to replace the third-generation Corvette with a new model, the immediate focus was to streamline manufacturing processes using the current production model, and to transition production from Missouri to Kentucky.

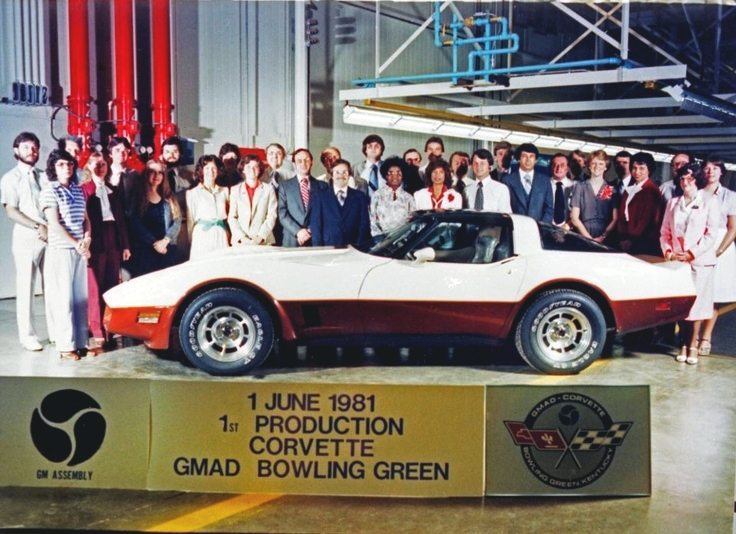

Bowling Green, Kentucky

On June 1, 1981, the first Corvette was completed at the new Bowling Green manufacturing plant. Interestingly, production of the 1981 Corvette continued at the St. Louis plant for the remainder of the model year (with the last Corvette rolling off the St. Louis line on August 1, 1981), meaning that Chevrolet was simultaneously producing their sports car in two locations. This opened up opportunity to increase the number of color choices offered for the 1981 Corvette since each plant could produce cars with different paint colors, though some of the more popular colors overlapped between the two plants.

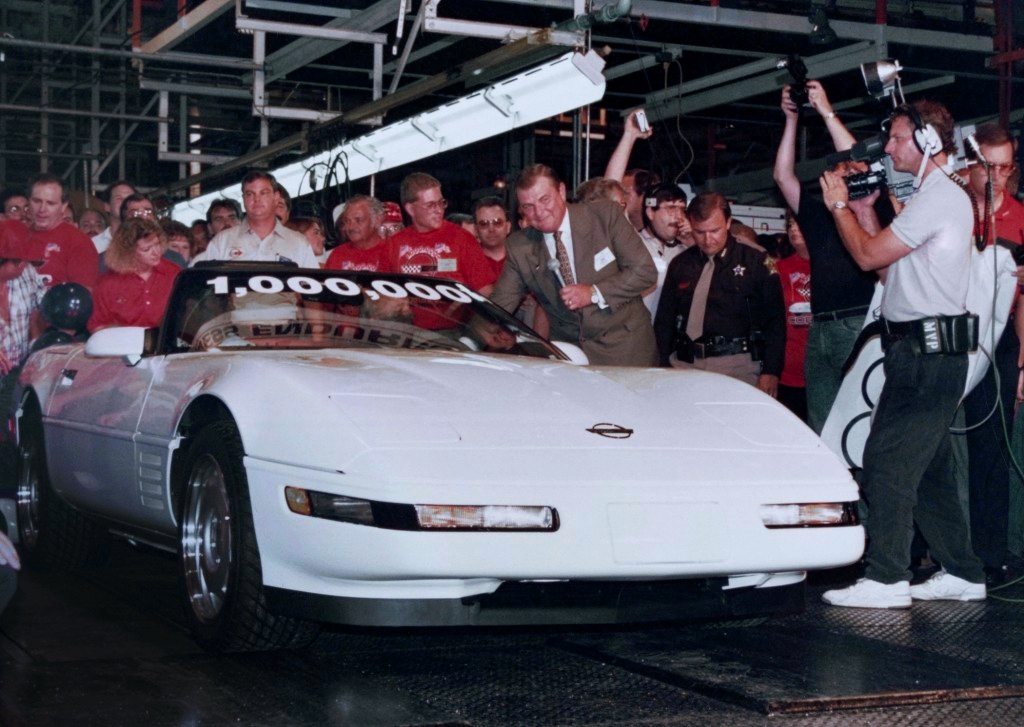

For the next 15 years, production of

the Corvette continued at the Bowling Green Assembly plant with virtually no change to the manufacturing infrastructure. In that time, the C3 gave way to the C4, with a year-long break in production (no Corvettes were produced in 1983 for the car’s 30th anniversary.) The production plant built the 1-millionth Corvette on July 2, 1992.

At the conclusion of the 1996 production year, the entire plant was renovated in preparation of manufacturing the totally-redesigned fifth generation (C5) Corvette. As before, production of the Corvette would continue unabated, and from 1997 to 2011, it operated with minimal changes to the production process.

The 50th anniversary of the Corvette was celebrated in June 2003 and was marked with a special 50th anniversary Corvette package.

The Cadillac XLR

The production plant also introduced the first non-Corvette vehicle built at the plant in June, 2003. Officially named the Cadillac XLR, the car was a luxury roadster that was to be Cadillac’s flagship car. The XLR was based on the sixth-generation (C6) Corvette’s Y platform, but featured its own unique styling, interior and suspension setup. The car featured a power retractable hardtop, and was equipped with a Cadillac Northstar engine.

While early production of the Cadillac XLR began in 2003, commercial production of the car coincided with the roll-out of the sixth-generation Corvette. The XLR was manufactured alongside the C6 Corvette from 2005 to 2009.

Two (of many) significant milestones were recognized during the production run of the sixth-generation Corvette. First, the 1.5 millionth Corvette rolled off the assembly plant on May 28, 2009. Just two years later, the plant celebrated its thirtieth anniversary in June, 2011.

The Once and Future Corvette Stingray

On May 4, 2011, General Motors announced that it would invest $131 million into the Bowling Green plant to support production of the seventh-generation Corvette Stingray. The re-design of the plant and the introduction of new manufacturing processes would take roughly two years to complete, but would also result in the creation of 250 new jobs as well as introducing a highly-refined manufacturing process for the C7 Stingray.

The plant upgrade in 2012–2013 included a brand new $52 million body shop that would enable the Corvette’s aluminum frame to be fabricated in-house for the first time. In addition, on January 30, 2013, GM announced that it would be investing $3.5 million to relocate its Performance Build Center – where the Corvette Z06 engines were produced – from Michigan to the Bowling Green Plant. This relocation would produce 30 new jobs at the plant.

The all-new 2014 Corvette Stingray was unveiled at the Detroit Auto Show on January 13, 2013. Production of the Stringray began 3rd quarter, 2013.

The Engine Build Experience

In March, 2015, Chevrolet introduced the exclusive “Engine Build Experience” as an option to consumers when ordering a 2015 Z06 Corvette. The program allowed Corvette aficionados to travel to Bowling Green, Kentucky to assemble their own 650-horsepower supercharged LT4 engine during the build of their cars.

The $5,000 package includes a full-day with a Performance Build Center engine assembly technician who:

- instructs and oversees the build.

- a personalized engine plaque identifying the owner/builder and the date of the engine build, and

- a professional photographer to document the entire experience.

In May, 2015, GM announced that it would invest $439 million into the plant for facility upgrades, including a 450,000 square-foot state of the art paint shop – an expansion that would increase the facility’s footprint by nearly fifty percent.

Construction of the paint shop began in the summer of 2015, and took approximately two years to complete. Despite the massive expansion, which included substantial technology upgrades not only to the paint shop but throughout the plant, Corvette production schedules were unaffected by the construction.

In December, 2015, GM announced another expansion project – this time a $44 million investment into the Corvette Plant’s Performance Build Center. The investment would increase the facility’s capacity and would include 36 new jobs.

But what about the tours – and the tourists?

Approximately 50,000 tourists from the world have traveled to the plant annually to catch a glimpse of the manufacturing process of the Corvette at the Bowling Green Assembly Plant. Additionally, the plant has long partnered with the National Corvette Museum to enable enthusiast the opportunity to watch their own Corvette being built, to take a personalized tour of the facility and to take special delivery of their Corvette as part of the Museum Delivery Program.

Currently, however, tours of the plant are suspended, due in large part to significant re-tooling that is taking place within the facility. While participants can still take delivery of their Corvette at the NCM, those wishing to watch their car travel the assembly line will be disappointed to learn that this option has been discontinued until further notice.

Although nobody really knows for sure the reasons behind the decision to suspend tours, many speculate that it’s because the plant is gearing up for another massive re-tooling, only this time it’s in preparation for the arrival of either a ninth-generation Corvette or else a sister-car; the mid-engine variant of the Corvette that fans have been dreaming of since nearly the beginning of the Corvette’s sixty-five year production run.

For more information about the Bowling Green plant, please visit its website at corvetteassembly.com.