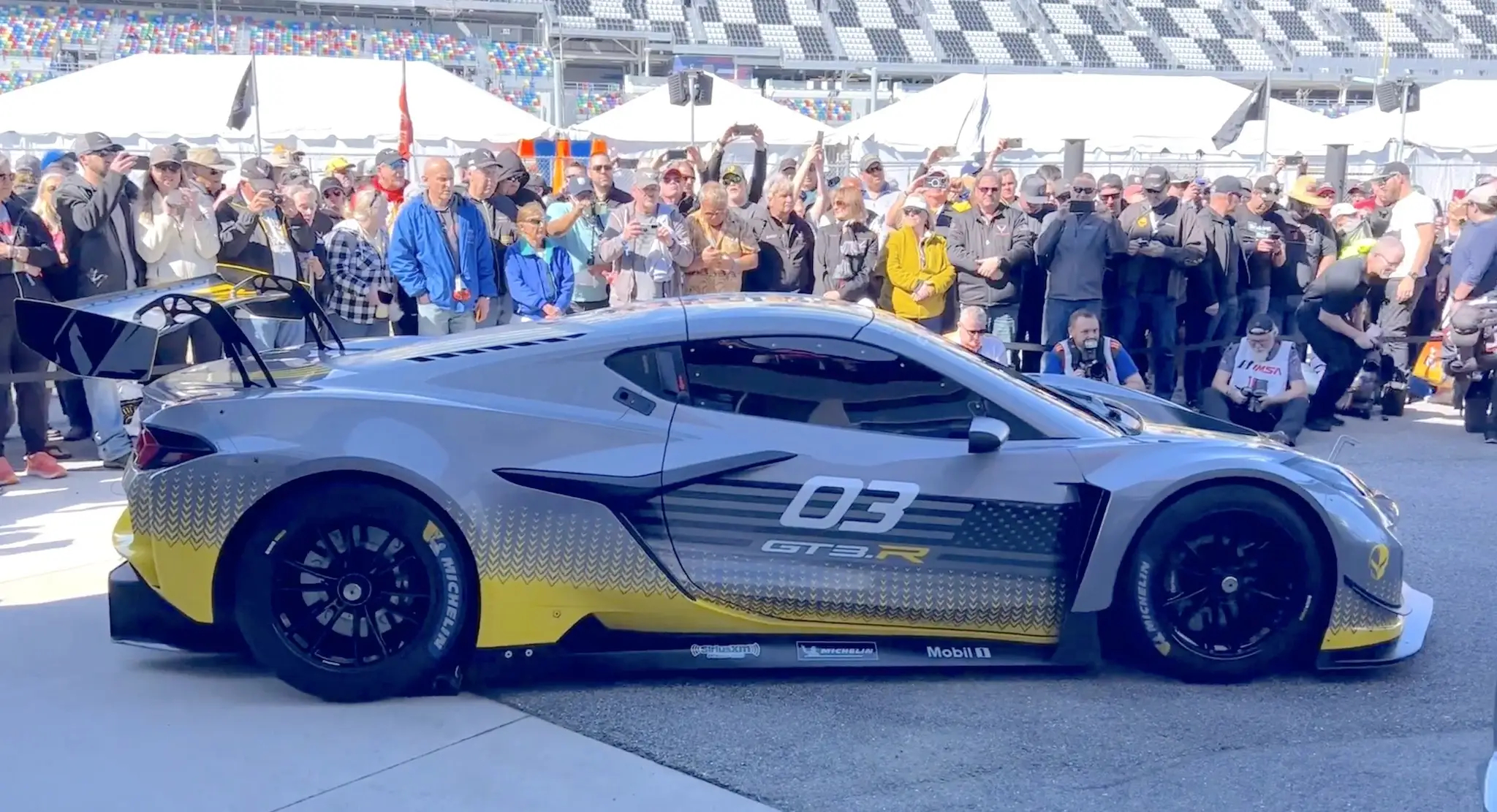

Chevrolet introduced the Corvette Z06 GT3.R race car in January 2023, a full year before its competitive debut at the 2024 Rolex 24 At Daytona. The purpose-built Z06 GT3.R replaced the Corvette C8.R, which was retired after the GTE Class racing was discontinued. Developed as a collaboration between GM’s Competition Motorsports Engineering and Pratt Miller Engineering, it is the first racecar from Chevrolet that completely satisfies the FIA technical regulations for GT3 cars.

The Z06 GT3.R shares its fundamental architecture with the eight-gen Corvette. At its heart is a potent 5.5-litre flat-plane crank V8 engine, just like in the road-going C8 Corvette Z06.

However, the Z06 GT3.R boasts some extensive modifications that make it suited to life on the track. These changes involve design tweaks, performance-enhancing add-ons, and safety features that transform the car into a purpose-built machine optimized for the rigours of professional motorsport.

Roll Cage

The addition of a roll cage to the structure of the Z06 GT3.R is one of the more obvious differences between the race car and its road-going counterpart. The Z06 GT3.R starts out as an aluminum chassis frame at Chevrolet’s Bowling Green Assembly in Kentucky.

It is then transported to Pratt Miller in Michigan, where a full purpose-built steel roll cage is welded onto a base plate and then secured to the chassis. The integrated steel cage sports some design modifications compared to the previous Corvette race car and now allows for easier entry and exit.

Side-Impact Crash Structure

The IMSA WeatherTech SportsCar Championship and GT World Challenge America are some of the main events where the Corvette Z06 GT3.R will compete. These events are highly combative, with intense wheel-to-wheel action. That is why the Z06 GT3.R features a side-impact crash structure in addition to the roll cage – features missing in the Z06 road car.

It was pioneered in the C7.R and has now been improved upon for the Z06 GT3.R. The crash structure, positioned between the driver’s side door and the roll cage, boasts a multi-layered design. An outer casing fabricated from carbon fibre and Kevlar provides exceptional impact resistance bolstered by an internal aluminum honeycomb structure that absorbs and distributes energy during a collision.

Engine

The powerplant here is a 5.5-litre flat-plane crank V8 that redlines at 8,500 rpm. It is produced at GM’s Performance Build Centre in Bowling Green, Kentucky. In the road-going Z06, it cranks out 670 hp, making it the most powerful naturally aspirated engine ever fitted on a production car. It’s the same engine in the Z06 GT3.R, with over 70% of its parts shared with the production Z06, including the coils, gaskets, fuel injectors and crankshaft. However, with a roughly 500-hp output, its potency is less, detuned in compliance with motorsport regulations. Some of the main differences in the Z06 GT3.R’s engine include a slimmer lower crankcase, which allows the engine to sit lower in the chassis. The GT3.R’s engine also has additional sensors and other race-optimized components.

Transmission

The power produced by the Z06 GT3.R’s engine is fed to the rear wheels via a racing-spec Xtrac P529 6-speed manual-sequential transmission. It contrasts with the Z06, which makes do with an 8-speed dual-clutch automatic transmission. The transmission in the Z06 GT3.R is designed to withstand the extreme demands of professional racing, including consistently high rpms, heavy loads and frequent shifts. It also gives the driver more control over shift points, which is crucial for optimizing performance on the track. The 8-speed dual-clutch transmission has the advantage of lightning-fast shifts but is more suited to the convenience of everyday driving.

Aero Package

A race car’s overall performance is not all about engine power. Its aerodynamic efficiency also significantly affects how competitive it is out on the circuit. The aero package is another key area where the Z06 GT3.R differs from the Z06. First, the underside of the Z06 GT3.R features a new purpose-built carbon fibre diffuser. It helps route air more efficiently from the front toward the rear in order to create an optimal level of overall stability and better handling as the car is being pushed to its limits. Then there is the massive rear wing for maximum downforce, much larger than you get with even the Z07 performance package on the standard Z06.

Suspension

Both the Z06 GT3.R and Z06 ride have a double-wishbone suspension on both the front and rear. However, the setups are quite different. For instance, the road-going Z06 comes standard with Magnetic Ride Control 4.0 dampers. This ingenious technology allows real-time adjustments to damping forces based on road conditions. There is no such luxury for the Z06 GT3.R. Its setup employs bespoke components, including stiffer springs, higher-rate dampers, and more robust bushings, all tuned for maximum track performance. These modifications significantly increase the car’s cornering grip, allowing it to navigate high-speed corners with incredible agility and stability. In essence, the Z06 GT3.R’s suspension favours raw speed and track prowess, sacrificing ride quality and comfort for ultimate on-track performance.

Price

The eight-generation Corvette Z06 is not exactly cheap, with prices starting from around $107,000. However, that price pales in comparison to what it will take to get you behind the wheel of the hard-core Corvette Z06 GT3.R. Private racing teams interested in the 2024 Chevrolet Corvette Z06 GT3.R must be prepared to shell out a whopping $735,000, making it the most expensive production Corvette ever.

The staggering price gulf reflects the difference between a high-performance street car and a purpose-built race car. The GT3.R is a bespoke machine meticulously engineered for life on the circuit. Its exorbitant price tag reflects the immense engineering effort, specialized components, and rigorous testing required to create a truly competitive race car capable of challenging for victories on demanding circuits.