The Definitive C3 Corvette Buyer’s Guide

For many of us, the idea of purchasing a Corvette has been a dream of ours since the time we first saw one of these classic cars on the open road. While all Corvettes are iconic, and while each has a loyal following of owners and enthusiasts who claim “their generation” is the best, there is little doubt that the third-generation Corvette is one of the most iconic generations of them all. Consider this – the C3 still holds the record for the longest production run of any generation Corvette, before or since. It was the generation that saw the Corvette “grow-up” from being a powerful track car and Le Mans racer to an iconic sports car synonymous with the American Dream. The C3 Corvette was owned by astronauts, celebrities and athletes all around the world. It was showcased in movies, on television and in mainstream music. It was the first-generation to serve as the official pace car of the Indianapolis 500.

Introduced in 1968 and produced until 1982, the third-generation Corvette has a sorted history full of highs-and-lows throughout its 15 year production run. Much of the evolution of this generation followed the economic and political climate of the United States in the late 1960’s and 70’s. While early model years (1968 – 1972) featured big engines producing massive horsepower, stricter Federal emissions regulations would cause Chevrolet to reduce engine output ratings in later models (1973 – 1982). At the same time, these changes forced Chevrolet to improve upon their engineering standards. By looking for ways to reduce the car’s weight and improve upon its overall design, they were able to continue to drive performance, even with the restrictions forced upon them.

Because of the dramatic changes that occurred throughout the C3’s fifteen-year production run (and the number of different powerplants offered by GM during that period), this C3 Corvette Buyers Guide was written a little differently than others in our “Buyers Guide” series.

We thought that it was important to understand the many differences between all of the C3 Corvettes. Our C3 Corvette Buyers Guide starts with an overview of each model year which highlights all of the details that made each of these cars unique. Because there were so many different engines introduced throughout the C3’s production run, and because so many of these Corvettes have had their engines swapped out over the natural course of time, we did not include a lot of mechanical information (known mechanical issues, common fail-points, work-arounds, etc.) for each of the engines introduced in the C3 Corvettes as a separate section.

Instead, we provided a list of the engines provided with each model year in the “Year By Year – What Are the Differences” section below, and included specific information such as engine size, displacement, horsepower ratings, etc. Should you have questions about a specific engine platform used in any of the C3 Corvettes, please contact us by clicking HERE. We’ll be happy to answer any questions you may have about a prospective Corvette (or anything else related to the C3 (or any-generation) of Corvette.)

The C3 Corvette Year By Year – What Are the Differences?

1968-1972

For serious Corvette collectors, the 1968 to 1972 model years contain some of the most sought-after Corvettes in the brand’s history. These models, which include the L88 and ZL1 Corvettes, are considered to be the “holy grail” of the third-generation production run. These Corvettes are some of the last to emerge without specific emissions controls systems or impact-absorbing safety bumpers. They contained the big, beefy engines – from the modest 350 cubic-inch small blocks to some of the most aggressive big-blocks ever produced by Chevrolet.

During these first four years of the C3’s production run, the Corvette’s outward appearance remained largely unchanged, with some notable exceptions that help to identify the cars. Corvettes built in 1968 and 1969 feature four vertical vents on the front fenders (just behind the front wheel wells), no fender flares and round exhaust tips. Conversely, Corvettes built between 1970 and 1972 feature more of an “egg crate” pattern in the front grill and front fender vents. They also feature fender flares and rectangular exhaust cutouts.

The late 1960’s and early 1970’s Corvettes were also distinguished for their robust powerplants with large engine displacements. The 1968 and 1969 Corvettes featured the 327 cubic-inch small-block and the 427 cubic-inch big-block engines. In 1970, these displacements increased to 350 cubic inch and 454 cubic inch respectively. Horsepower increases were proportionate with the growth of these engines, achieving peak outputs that exceeded 450 horsepower before government-mandated emissions restrictions and safety programs would begin to reign-in the performance of these powerful engines.

Although there are Corvettes from this era (including the L88, L89 and LT1) that trade hands among serious collectors for millions of dollars apiece, there are many more 1968–1972 Corvettes available today for prices that make ownership of an early-era C3 not only possible, but affordable as well.

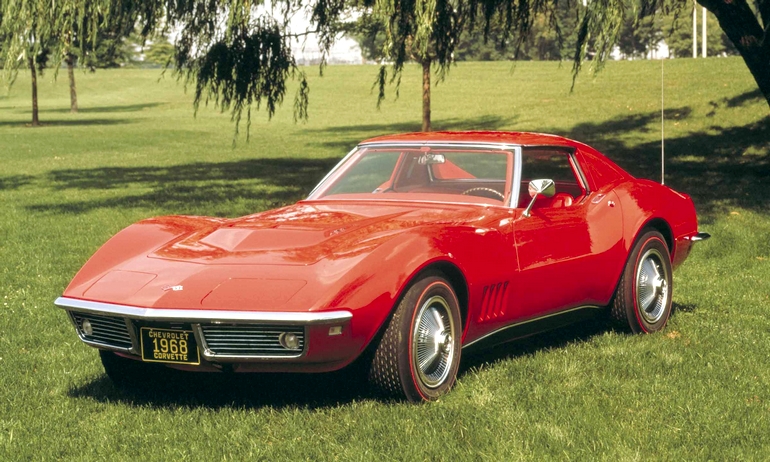

1968 Corvette

Although it featured a completely new body design, the 1968 Corvette included many of the same powertrain offerings as the out-going 1967 C2 Corvette – with one notable exception. In 1968, General Motors introduced the Turbo Hydra-Matic three-speed automatic transmission to replace the earlier two-speed Powerglide automatic. Additionally, Chevrolet offered six optional engine platforms to consumers in the 1968 Corvette ranging from the standard 300 horsepower, 327 cubic-inch small-block engine (which came paired to a three-speed manual gearbox) to the high-output 435 horsepower, 427 cubic-inch L71 big-block V8 engine. (NOTE: All of the available engine options are listed above.)

The 1968 Corvette had a harsher ride than its predecessor, a fact that did not go un-noticed by the automotive press. The car also had a tendency to understeer, (a regrettably recognizable trait of the early-generation Corvettes,) which was a direct result of installing stiffer rear springs to reduce front end lift during acceleration. The rear roll center was also lowered, which, when coupled with the suspension tuning, further added to the under-steering issue.

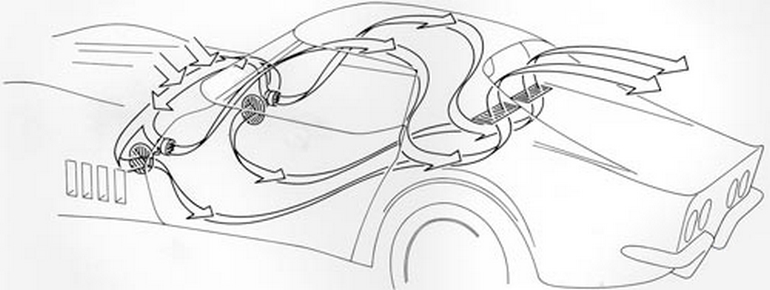

The C3’s battery was relocated behind the seats which also provided additional room under the hood. The second-generation Corvette’s side vent windows were eliminated in favor of a new fresh-air “Astro-Ventilation” system. The Astro-Ventilation system routed fresh moving air in through the front cowl, around the interior airspace, and out through grilles located in the rear deck right behind the back window. For maximum ventilation, the rear window could also be removed.

Shoulder belts were introduced in 1968 as a “no-cost” option for all Corvette coupes (although the option remained an additional expense on convertible models.) Additionally, the 1968 model year included an electric rear-window defroster, speed warning indicator, AM/FM stereo radio, and a high-tech, futuristic fiber-optic light monitoring system.

The 1968 Corvette sat lower than its predecessor had. It was also longer, wider, and heavier. The overall length of the new Corvette increased from 175 inches to 182 inches, and most of this was the direct result of the greatly increased overhanging nose assembly at the front of the car. In fact, the wheelbase remained unaltered from the second-generation Sting Ray’s 98 inches. The track width increased at both the front and rear of the car, from 56.5 inches to 58.7 inches in the front and from 57.0 inches to 59.4 inches in the rear. The car’s weight also increased by nearly 200 pounds over the 1967 Sting Ray, putting the 1968 Corvette’s curb weight at approximately 3,400 pounds.

The 1968 model year set a new Corvette sales record (up to that point in time) at 28,566 units sold, which was up approximately 5,000 units from the final Sting Ray.

1969 Corvette

The 1969 Corvette was largely a “carry-over” of the 1968 model. Almost all of the changes to the “sophomore” year of the third-generation Corvette were made to correct for design and engineering errors in the initial design. These “errors” were often identified from feedback from both the automotive media and consumers alike.

Exterior alterations were fairly minor – with one notable exception. For 1969, Chevrolet returned to using the “Stingray” designation for its new Corvette, although for the C3, the name was now a single word (unlike the “Sting Ray” used on all second-generation Corvettes.) Elsewhere, the 1969 Corvette received an all-welded, 5-cross-member, ladder-type, steel-reinforced frame that was intentionally “stiffened” to help reduce body vibration. The car’s exterior door handles were relocated from the conventional door grip with thumb-release button to a single-piece door lever that was depressed as the door was gripped during opening. A new headlight washer system was introduced and the windshield washer jets were relocated to the wiper arms. Lastly, a trunk-mounted luggage rack was offered to consumers to increase the Corvette’s overall luggage capacity.

The interior received a number of minor, but significant changes. First, a new, smaller steering wheel was introduced, trimmed back an inch for more under-rim thigh clearance. The interior door handles and control knobs were redesigned to improve upon safety. The ignition switch, which had been mounted on the dashboard since Corvette’s inception in 1953, was moved to the steering column for the 1969 model year, where it combined with the newly mandated column lock for additional security. A warning light was added to inform drivers if the pop-up headlights did not open completely. A flexible dash mounted three-section map pocket was included to help make up for the lack of a proper glovebox. Headrests became a standard feature although they could be deleted when ordering the car. Lastly, Zora Arkus-Duntov got GM to approve a $120,000 tooling change that opened up the inner door panels a half-inch per side, allowing occupants additional shoulder space.

The 1969 Corvette received an extensive array of safety features that were specifically design to protect both the occupants of the car as well as the car itself. These included an energy-absorbing steering column, seat and shoulder belt restraints, an energy-absorbing instrument panel, padded sunvisors and a reduced-glare instrument panel for improved visibility during night driving. Additionally, an anti-theft ignition system was installed with featured both anti-theft steering and transmission locks as well as an anti-theft ignition key warning buzzer that would sound whenever the keys were left in the ignition cylinder.

Like the 1968 model before it, the 1969 Corvette was offered to consumers with a number of different powerplants, from the standard 300HP, 350 cubic-inch small block to the ultra-rare, incredibly valuable 435HP, 427 cubic-inch L88 big-block engine.

Despite the improvements that were made to the 1969 Corvette, some critics continued to take issue with the Stingrays “dismal build quality, styling eccentricities, and overall lack of finesse.” However, the criticisms did nothing to deter consumers from purchasing it. In 1969, Corvette sales increased by more than 10,000 units to a total of 38,762 Corvettes sold that year. Of those sold, 22,129 were coupes and the other 16,633 were convertibles.

1970 Corvette

The 1970 Corvette made its formal debut in late February. While much of the car was a carryover of the 1969 model, the 1970 Corvette did include a number of small-but-significant design improvements. These design changes, which had been first introduced on a concept vehicle dubbed the “Aero Coupe,” included many elements which proved GM‘s interest in moving the Corvette away from its current role as a pure sports car (the ZL-1 notwithstanding) towards the blended role of becoming a Luxury Sports car.

The 1970 Corvette featured an egg-crate patterned grille, matching louvers along the fenders (which replaced the four gills of the 1968 and 1969 model years), and more deeply flared wheel house designed to reduce the severity of the bodyside tuck-under, which had been discovered as being susceptible to stone damage. Additionally, the parking lights were squared off and set into the corners of the grille. Mandatory side marker lights at the front and rear of the car were made larger and were better integrated into the design than those of earlier model years. In the back of the car, new rectangular exhaust pipe tips were recessed into the underside of the rear bumper/fascia assembly. A number of detail refinements were also made to the taillights and the stainless steel rocker moldings.

The interior of the 1970 Corvette was improved upon in a number of areas. The seats, which had been re-designed in 1969, underwent another design change that added an inch of urgently needed headroom as well as better lateral support. The headrests were integrated into the seat design. A more accessible release button was introduced for the seat back hinge. The inertia reels for the shoulder harnesses were tucked away more neatly in the rear quarters which opened up more space in the trunk area. The seatbelts were fed through slots in the seat backs which made them more integrated into the overall design.

Some 1970 Corvettes included a custom interior (an option that could be ordered when purchasing the vehicle new (though there was no RPO assigned to this option.)) These “custom interiors” gave the 1970 Corvette a “dressed-up” look. When so equipped, these Corvettes featured leather-trimmed seats, cut-pile, door-to-door carpeting, a leather boot (for manual transmission shift levers), and wood-grain trim on the console and doors.

The previously optional Soft-Ray Tinted Glass option (RPO A01) was made standard equipment for the 1970 model year. As a result, all 1970 Corvettes received evenly tinted glass on all windows.

Mechanically, there were many carryovers from the previous model year. The small-block engine lineup remained the same at the two lower power ratings (300 horsepower and 350 horsepower respectively). However, GM did introduce a new solid-lifter, small block engine that they designated the LT-1. Corvettes equipped with this engine received a special hood dome surrounded by striping and “LT-1” lettering.

For the 1970 model year, Chevrolet introduced a big block 427 that was stroked out to a full 4.00 inches and 454 cubic inches. It was the first time that the stroke had been increased since the engine had been introduced in its more conservative iteration – a 396 cubic-inch big block – in 1965. The added cubic inches in the Corvette were actually the byproduct of Chevy’s need to expand the engine’s size to counterbalance the loss of performance in its regular passenger cars due to the mandatory reductions in exhaust emissions as required by state and federal laws.

There is a more limited number of 1970 Corvettes available than other model years from that era. This is due to a late production start on the model year as the result of a UAW strike. Chevrolet produced just 17,316 Corvettes in 1970, comprised of 10,668 coupes and 6,648 convertibles.

1971 Corvette

The 1971 Chevy Corvette remains one of the least changed models in design (when compared to the preceding model year) in the Corvette’s entire production history. Because of this, it was decided by Chevrolet management that they should treat the 1971 model year as an extension of the 1970 line, which meant that the Corvette remained essentially unaltered between the two model years.

Because the production of the cars would remain virtually unchanged from 1970 to 1971, production lines in the St. Louis Corvette plant were able to work in earnest to manufacture a more trouble-free car. The 1971 Corvette also arrived in conjunction with Federally sanctioned mandates that enforced the reduction of exhaust emission output. The bi-product of this sanction is that GM began manufacturing engines that could operate on gasoline rated at a maximum 91 octane. This mandate also resulted in the manufacturing of engines with lower compression ratings and horsepower.

All of the engines offered in the 1971 Corvette were impacted by this mandate. The solid lifter, small block LT1 engine was now rated at a modest 330 horsepower with a 9.0:1 compression ratio. The LS5 454 cubic inch big-block produced 365 horsepower at 4800 rpm, and a new aluminum-head big-block engine identified as the LS6 was rated at 425 horsepower at 5,600 rpm.

There were minor refinements made to the 1971 Corvette. These included an easier-to-open fuel filler door, and an automatic transmission selector quadrant that illuminated during night time operation. However, these minor refinements were the only thing that separated the 1971 model from earlier years. The 1971 Corvette would be the last Corvette model to feature the fiber-optics light monitoring system. It is believed that many late model 1971 Corvettes were actually manufactured without the fiber optics.

For 1971, Chevrolet offered consumers two special purpose (racing) packages.

The first of these was the RPO ZR1 package which utilized the aforementioned LT1 engine, and also included a heavy-duty, four-speed, close ratio transmission (RPO M22), heavy-duty power brakes, a special aluminum radiator, a metal fan shroud, a transistor ignition, and a revised suspension with special springs, shocks, spindle-strut shafts, and front and rear stabilizer bars (though it has since been determined that the 1971 ZR1 has appeared with and without rear stabilizers.) When equipped with the ZR1 package, consumers were unable to include many of the more “luxurious” amenities available such as power windows, a rear window defroster, air conditioning, power steering, deluxe wheel covers, an alarm system, and any type of AM/FM radio.

The second special purpose package that Chevrolet offered was RPO ZR2. This second special purpose package was identical to the ZR1, except that instead of a small block LT1 engine, the ZR2 came equipped with the aforementioned 454 cubic inch LS6 engine. Like the ZR1, the ZR2 package included the same ordering restrictions – namely none of the “creature comfort” amenities that were appealing to many consumers.

In total, only eight Corvettes were ordered with the ZR1 option, and only twelve were ordered with the ZR2, making these cars extremely rare – and valuable – in today’s collector car market.

Chevrolet produced a total of 21,801 Corvettes in 1971. Of these, 14,680 were coupes and 7,121 were convertibles.

1972 Corvette

There were virtually no physical or mechanical changes made to the 1972 Corvette from the previous year. Most of the “changes” made to the 1972 model centered on options that were no longer available to consumers.

The ZR-2 package was no longer offered to consumers. The elimination of this package was the direct result of the LS-6 engine being eliminated from production by Chevrolet. Similarly, all of the engines offered for the 1972 model year suffered from a loss of power thanks to mandatory emissions restrictions that were implemented that year. The 1972 Corvette’s stock engine – designated ZQ-3 – was rated at a conservative 200 brake horsepower. The LT-1 was rated at 225 horsepower and the LS-5 was rated at 270 horsepower. (NOTE: starting in 1972, Chevrolet begin publishing engine ratings in NET horsepower, resulting in output numbers that looked more exaggeratedly low when compared to earlier production years.)

Both the coupe and the convertible models featured the “horn-honking” alarm system as a standard option. The alarm could be armed/disarmed via a lock cylinder located at the rear of the car.

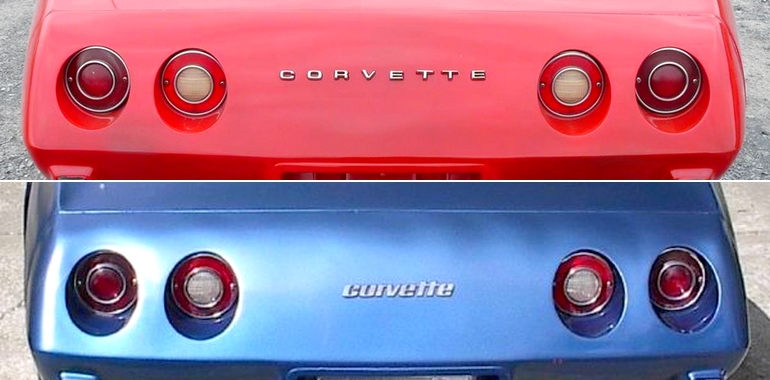

The 1972 Corvette had the distinction of being the last model year to feature both front and rear chrome bumpers, a bright egg-crate grill, side-fender grills and a removable rear-window.

In total, 20,496 Corvette coupes and 6,508 convertibles were manufactured in 1972.

1973-1977

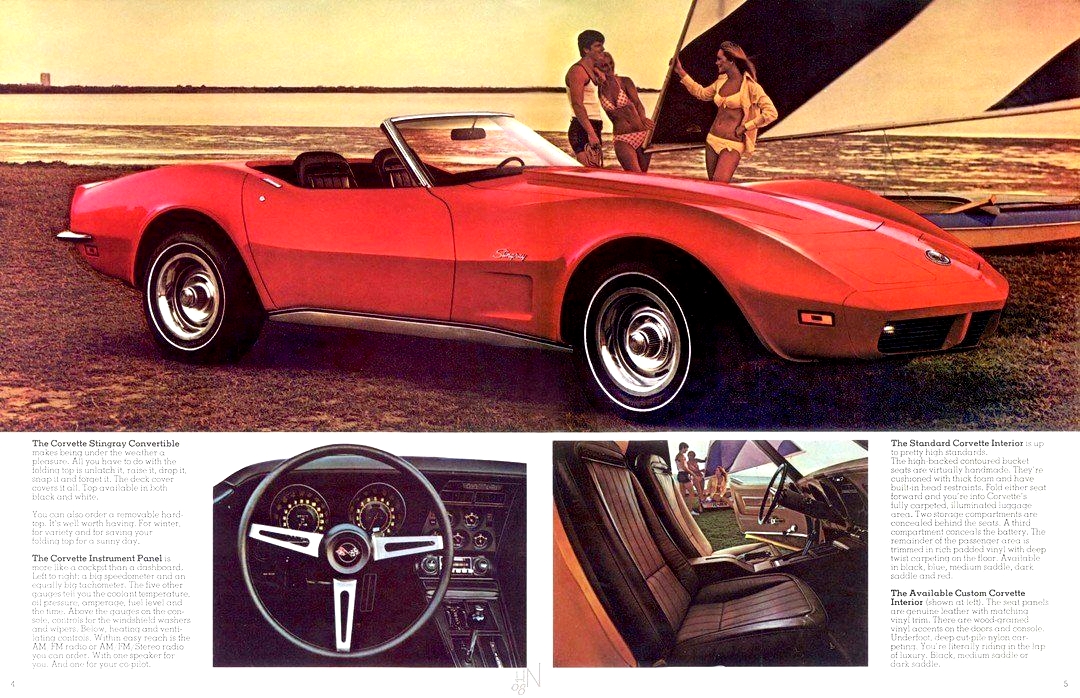

The “middle years” of the C3 Corvette were definitely a time of transition for the brand. Government regulation and stricter emission standards had an adverse impact on engine horsepower/output as did increasing fuel costs, oil embargos and foreign trade policy. All of the forces at work in the world definitely added to the challenge of building more efficient engine options that improved upon fuel economy and reduced exhaust emissions. The days of building “big horsepower” were over – at least as far as the third-generation Corvette was concerned. The mid-1970’s were the “end of the line” for multiple key elements that had been synonymous with the Corvette since 1953: the factory big-block V8 was discontinued in 1974; 1975 was the last year of a convertible model until 1986 and the 1976 model had the dubious distinction of being the only Corvette to sport a steering wheel lifted from the lowly Chevy Vega. Engine choices dwindled as well with the L-82 emerging as the hot engine.

While engine output suffered, the aesthetics of the Corvette improved as the third-generation Corvette matured. The 1973–1977 Corvettes retained the “sugar scoop” rear window but switched to urethane bumpers and single slot fender vents. The 1973 model was unique as it was the only year with a soft front end and chrome rear bumpers. As the Corvette transitioned away from being a “pure sports car”, it took on a more luxurious overtone. Corvettes were now being offered with genuine leather, automatic transmissions, air conditioning etc. The more “creature comforts” that were built into the C3, the better the car sold. In fact, Corvettes equipped with 4-speed manual transmissions accounted for less than ten percent of total production. GM sold more than 200,000 C3 Corvettes during this period.

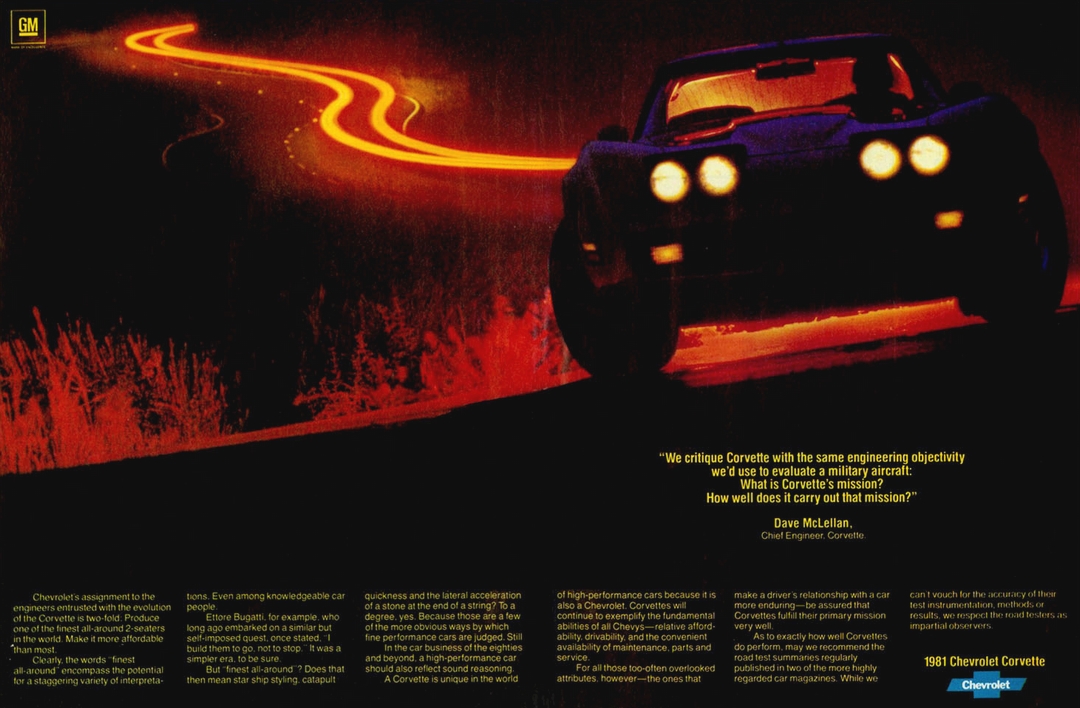

Lastly, Zora Arkus-Duntov retired in 1975 and Dave McClellan took over the coveted job of Corvette chief engineer. For the first time since 1953, the Corvette enterprise was helmed with new vision.

1973 Corvette

The 1973 Corvette marked the 20th anniversary of the Corvette. It also marked the first re-design of the C3 since it was introduced in 1968.

The changes to the 1973 Corvette included a new front-end on both the coupe and convertible models. The Corvette’s nose was increased by approximately two inches and featured a steel bumper that was covered by a deformable urethane plastic fascia that was painted to mach the body color of the car. A longer hood panel was also introduced. The new hood shrouded the parked wiper blades and allowed for the return of a cowl-induction system controlled by a solenoid-operated value that was built into the hood.

The 1973 Corvette’s rear window, which had been removable on earlier models of the C3 Corvette, was now fixed in-place. The fixed window added an additional inches of rear storage space to the car thanks to the removal of the rear-window storage shelf.

An optional set of wheels were offered for the 1973 Corvette. Listed under RPO YJ8, these wheels were offered for just one year due to a design flaw in the material used to fabricate the wheels. While only four sets of wheels were ever recorded as being sold during production of the car, it is believed that Chevrolet produced as many as 800 sets of these unique aluminum wheels. When looking at 1973 Corvettes that might have been equipped with this option, these wheels can be identified by casting number 329381 – and make for a unique and collectible component with these cars. It is unknown how many sets of the YJ8 aluminum wheels still exist today.

Mechanically, the 1973 Corvette featured several engines including: the base 350 cubic-inch engine (RPO L48) rated at 190 horsepower, an optional small block (L82) rated at 250 horsepower and an optional 454 cubic-inch big-block (LS4) rated at 270 horsepower.

Chevrolet produced 30,464 Corvette in 1973, of which more than 80% (25,521 units) were produced as coupes.

1974 Corvette

The 1974 Corvette was the final model-year to offer an optional big-block, 454 cubic-inch V-8 engine. It was also the final year that Chevrolet would manufacture engines that ran on leaded gasoline – a decision that aligned with an industry-wide requirement to install catalytic converters in every 1975 (and later) models.

The exterior of the 1974 Corvette received a new rear-end treatment designed to comply with a new, Federally imposed five-mile-per-hour impact standard. Like the front bumper re-design on the 1973 Corvette the year before, the 1974 Corvette’s rear bumper now featured a urethane plastic skin covering an aluminum impact bar that was mounted to the Corvette’s chassis by two, telescoping brackets. The rear fascia assembly featured built-in recesses for the license plate and the car’s taillights and was actually made of two “halves” divided by a vertical, center seam – a detail that is unique to the 1974 Corvette.

The interior of the 1974 Corvette received only minor enhancements. The most notable improvement for the 1974 coupe was the introduction of an integrated shoulder belt/lap belt assembly. Shoulder belts remained an optional feature on convertible models. For convertibles equipped with a shoulder belt, they remained a separate assembly from the lap belts. The rearview mirror was increased in size from 8 to 10 inches on both the coupe and the convertible.

Mechanically, a number of refinements were made for the 1974 Corvette. The standard engine output was increased to 195 horsepower. The Turbo-Hydra-Matic automatic transmission was refined to make it more durable (and ended up being installed in nearly two-thirds of all 1974 Corvettes.) The radiator was re-designed for more efficient cooling at low speeds. The power steeping pump was made more durable via the use of magnets, which were installed to attract/capture debris in the power-steering fluid. Downstream from the engine, resonators were added to the exhaust system, which enhanced the tone of the car during operation. An inexpensive option (RPO FE7) resulted in the installation of the Gymkhana Suspension package, which featured a higher-rate spring assembly and firmer, specially calibrated shocks.

Chevrolet produced a total of 37,502 Corvettes in 1974. Of these, 32,028 were produced as coupes and 5,474 were produced as convertibles.

1975 Corvette

The 1975 Corvette was almost identical to the 1974 Corvette, with the exception of the introduction of front and rear bumper pads. These pads were integrated into the urethane front and rear bumpers and offered drivers additional protection in parking lots, curbs and other cars. The interior of the front bumpers also received a honeycomb core to increase structural rigidity. The rear bumper was re-designed as a single-piece assembly and received inner shock absorbers to reduce damage in the event of an impact condition.

Mechanically, the 1975 Corvette came equipped with just two engine platforms – the stock, 165 horsepower, 350 cubic-inch engine and the optional L82 205 horsepower, 350 cubic-inch engine. There were a limited number of big-block engines offered at the start of the production year, but this option was dropped early in the model year, making it a rare option on the 1975 Corvette.

Elsewhere, the car received a “headlights-on” warning buzzer as part of a Federal mandate. An internal bladder was added to the fuel tamp to help prevent gas fumes from escaping the tank and preventing air from entering and/or getting trapped in the tank. Hood emblems featuring the engine designation “L82″ were introduced in 1975 (though many Corvettes equipped with the L82 engine that year did not receive the badging on the hood.) Lastly, the 1975 Corvette was the final model year to feature the Astro-Ventilation System (first introduced in 1968).

The 1975 Corvette marked the final year that a convertible-option would be offered on the third-generation model.

A total of 38,465 Corvettes were built in 1975, of which all but 4,629 units built that year were coupes.

1976 Corvette

Many automotive critics agree that the 1976 Corvette is one of the best-looking model years of the C3-generation.

For starters, the 1976 model no longer featured a cowl-flap. Instead, a simpler system was developed that rammed air through a duct that ran forward of the radiator support to scoop up some of the cooler, outside air that fed the radiator. While the cowl-induction system was eliminated on the 1976 Corvette, the intake grill remained on the car until 1977.

Chevrolet introduced two different styles of rear bumper/fascia assemblies on the 1976 Corvette. The first fascia was actually a carryover from the 1975 model year and featured the word “CORVETTE” in a large font that filled the width of the surface area between the rear headlights. The second, which was introduced in 1976, featured the word “CORVETTE” in smaller, recessed letters.

Perhaps the most notable change for 1976 was the re-introduction of the aluminum wheels that had first been introduced in 1973. Listed as option RPO YJ8, the option included a set of four aluminum wheels plus a full-size spare. The wheels were manufactured by Kelsey Hayes in Mexico and could be identified by the source and build location information etched on their inside surface.

The interiors of the 1976 Corvette remained mostly unchanged from the previous year with one, notable exception – the introduction of a four-spoke, “sport’ steering wheel. Many Corvette enthusiasts were less than enamored with the introduction of the new steering wheel as it was the same as that found in the sub-compact Chevy Vega GT, along with a number of other Chevrolet models introduced that year.

A steel under pan was added to the car to increase the car’s rigidity and to act as a heat shield/insulator between the Corvette’s catalytic converters and the vehicle cockpit. The installation of a catalytic converter on the 1976 Corvette actually increased the engine horsepower slightly on all engine platforms. The L48 engine saw an increase of 15 horses, pushing its total horsepower to 180bhp. The L82 increased to 210bhp. Unfortunately, the L82 engine was not offered in California in 1976 (and 1977) because it did not meet the state’s tougher emissions standards.

Four-speed manual transmissions were also banned out west for those same model years. An automatic transmission was the only option available to Californians in 1976 (and 1977). However, it wasn’t the Turbo Hydra-Matic 400 that had been previously used behind all Corvette engines. Instead, Chevrolet mandated use of the less robust TH 350 automatic transmission.

Power steering and power brakes became standard on all 1976 Corvettes midway through the model year (though 173 early-production Corvettes were produced without power steering).

Chevrolet sold a total of 46,558 Corvettes in 1976, breaking the previous Corvette sales record set in 1969.

1977 Corvette

Like several of its earlier iterations, the 1977 Corvette received only minor modifications from the previous model. However, the 1977 Corvette did incorporate a significant manufacturing milestone for the Corvette brand – it was the year that Chevrolet produced it’s 500,000th Corvette.

Outwardly, the car was virtually identical to the 1976 model, save for the introduction of a reworked luggage and roof panel rack (RPO V54) that could be used to transport the car’s T-tops (instead of placing them in the Corvette’s lidless trunk.) With regard to the T-tops, glass roof panels were introduced as a new option at the start of the model year, though General Motors later canceled the option because of a reputed dispute with the supplier over sales rights. The most notable change from 1976 to 1977, however, was the removal of the Stingray nameplate from the Corvette’s front fenders. It was replaced by Corvette’s traditional crossed-flags insignia.

Moving inward, the 1977 Corvette did see a few notable refinements. First, the interior center radio console was redesigned to accept a broader array of Delco audio decks (including an AM/FM/cassette stereo as a first-time option). The instruments on the dashboard were restyled to provide drivers greater visibility. The climate controls were simplified. The manual transmission lever was lengthened, placing the shift ball higher up in relation to the disengaged handbrake. The steering column was shortened by two inches to allow for more of an “arms out” driving posture. Additionally, the shorter steering column improved driver accessibility in-to, and out-of, the new Corvette. Mated to the steering column was a new leather trimmed steering wheel. The alarm switch was moved again and was incorporated into the left door-lock button assembly. The sun visors were revamped to allow them to swing from the windshield to the side windows. Even the mounting location of the rearview mirror was shifted from above the windshield to the windshield itself. Lastly, for the 1977 model year leather upholstery came standard with the Corvette while cloth seats with leather bolsters were an optional no-cost alternative.

For cars equipped with the optional tilt-telescopic steering column (RPO N37), the 1976 style steering wheel was carried over for the 1977 model year. While tilt and telescopic adjustments remained optional, Chevrolet did introduce a new feature to the 1977 Corvette – namely the new “Smart Switch” – a steering column stalk that combined the headlight dimmer and wiper/washer functions with the turn signals.

Mechanically, the 1977 Corvette went essentially unchanged from the 1976 model year. As in 1976, the 1977 Corvette came standard with a 180 horsepower, 350 cubic-inch, small-block Chevy engine mated to a 4-speed, wide-ratio manual transmission.

Between August 23 and September 7, 1976, the Flint Engine Plant (the plant where the small-block 350 was manufactured) began using blue paint in place of the traditional “Chevy Orange” paint that had normally been applied to Corvette engines. Thus, early 1977 model year Corvettes continued to feature the familiar orange block, while later production engines were blue.

A total of 49,213 Corvettes were sold in 1977, setting another single-year sales record for the brand.

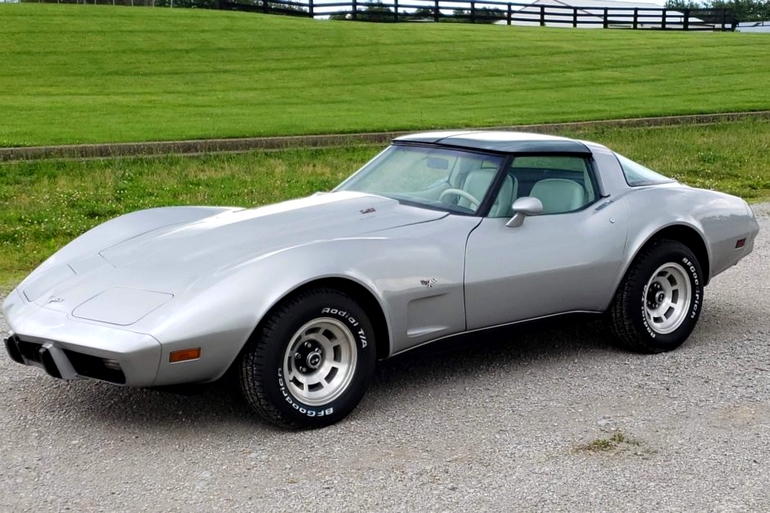

1978-1979

After several years of being built without much revision to the car’s design, Chevrolet decided to refresh the Corvette’s design in 1978. Gone forever was the “sugar scoop” rear window assembly. Instead, Chevrolet introduced a wraparound glass window that vastly improved storage space and rear visibility when operating the car. A new dashboard and console assembly were introduced, allowing for increased versatility on the types of audio equipment that could be installed in these cars. Even the stock L-82 was enhanced, receiving a bump in horsepower (up to 220 over the stock 210 from the outgoing 1977 model.) Further refinements would continue into 1979 (more on this below). It seemed that GM had taken a calculated risk by waiting on introducing any design changes for as long as they did – but the risk paid big dividends. Between 1978 and 1979, more than a 100,00 Corvettes were sold, proving that even a 10 year old design (remember that the C3 was first introduced in 1968) could remain relevant with a little vision.

1978 Corvette

While the 1978 Corvette brought a large number of refinements to the brand, its most significant milestone was the fact that the 1978 model marked the Silver (25th) Anniversary of the brand!

Chevrolet saw the 25th anniversary of the Corvette as the perfect opportunity to re-envision the C3’s overall design. The result was the removal of the old “flying buttress” sail panels and flat-rear window in exchange for a large, compound curved window. In so doing, Chevrolet engineers not only gave the aging third-generation Corvette a new look, but they also brought about the return of the Corvette fastback, which had been notably absent since 1967.

In addition to the new rear window, Chevrolet introduced a special “25th Anniversary” package to commemorate the car’s silver anniversary. The Silver Anniversary model was finished in Bill Mitchell’s favorite color – silver. It was later decided that all 1978 “25th Anniversary Corvettes” would include a silver paint scheme. The anniversary cars also included special “Silver Anniversary” badges, aluminum wheels, and dual “sport” outside mirrors as mandatory options.

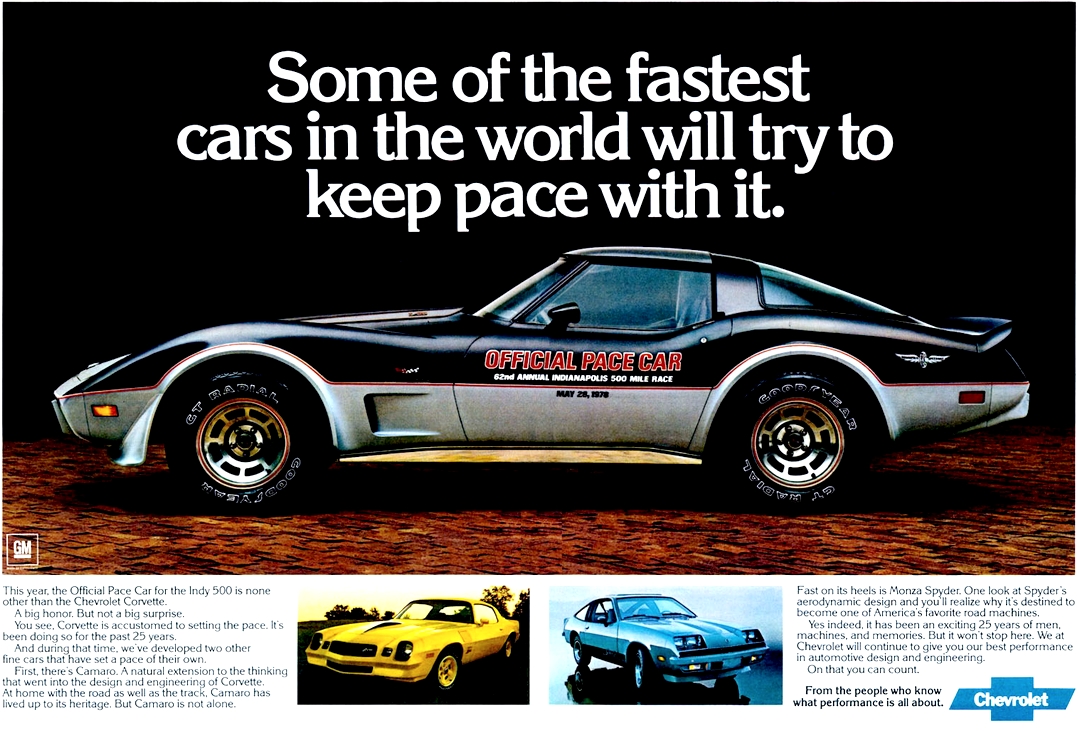

To further commemorate Corvette’s 25th anniversary, Chevrolet also introduced their first-ever Corvette Indy Pace Car. The car, much like the Silver Anniversary Edition, featured a special, two-tone paint scheme, although for this model, the color choice was black over silver metallic with a bright red pinstripe between the two tones of paint. The Corvette Indy Pace Car also featured a front and rear spoiler, both of which added a more dramatic appearance to the car, though neither offered much in the way of additional downforce (or other functionality.) The front spoiler was similar to the one installed on the 1978 Pontiac Trans Am. It wrapped under and around the front of the car, blending into the wheel wells. The rear spoiler, on the other hand, curved down at its outbored ends to meet the bodysides of the Corvette.

The interior of the Corvette Pace Car featured either full silver leather or leather/gray cloth upholstery and gray carpeting. Chevrolet introduced a new, thin-shell seat design that featured more lumbar support. These seats were originally slated for the 1979 model, the development program was accelerated so that these new seats could be introduced as part of the 1978 Pace Car package.

The “Limited Edition Indy Pace Car Replica” Corvette actually accounted for 15 percent of all the Corvettes manufactured that year.

All 1978 Corvettes received other updates as well. Every Corvette would undergo a series of cosmetic and functional updates, including receiving special “Silver Anniversary” badging on the exterior of the car. The interiors received far more attention. The speedometer and tachometer were now encased in squared-up instrument panel housings, matching the previous year’s revamped console gauges. A genuine glovebox was added. The interior door panels featured an all-new design with armrests that were screwed onto the door instead of being molded into the door as they had been since 1965. The doors now featured integral door pulls. A single piece, fully padded dashboard with a front mounted cluster was developed for easier removal in such cases where service was required. Windshield and wiper controls were moved back to the instrument panel, but the dimmer switch remained on the steering column. The three-point seat belts were given a single inertia reel, and belt guides were eliminated.

All of the 1978 Corvettes also featured an updated anti-theft system. The new security system, which was installed as a standard option on all Corvettes, was modified from previous years to include activation in the event that the T-tops were to be tampered with in any way.

Glass T-tops were offered for the first time in 1978, though GM had originally intended for them to be available on the 1977 model. Both the glass tops and the normal fiberglass T-top panels were modified to provide additional headroom to both the driver and passenger, and both included a key-lock assembly that helped further secure them to the vehicle by securing each T-top latch from being operable when locked.

Power ratings diminished some as a result of stricter emission standards, and also as a result of the government’s new Corporate Average Fuel Economy (CAFÉ) mandates that took effect that year. As with the 1977 Corvette it, the 1978 model featured two basic versions of the 350 CI small-block V-8 engine from which consumers could choose. The base L48 produced 185 brake horsepower in every state except California. For California and high-altitude areas, the engine generated 175 bhp. The optional L82 engine featured an engine output of 220 brake horsepower via a dual-snorkel air intake system which allowed the delivery of a larger volume of cool air into the engine while a revamped exhaust system that featured larger exhaust and tailpipes along with lower restriction mufflers had been designed to reduce back pressure.

Elsewhere, the car remained very similar to the 1977 Corvette. A few changes were made, including a larger fuel tank, which now held 24 gallons of gas (versus the 17 gallon tank used on the previous year.) The tank itself features an internal molded plastic liner cased inside of a steel shell. To accommodate the larger fuel tank, Corvette introduced a smaller, lighter weight spare tire. Wider 60-series tires were also introduced on the 1978 Corvette as an option.

In total, Chevrolet produced 46,776 Corvettes in 1978.

1979 Corvette

The 1979 Corvette provided further refinements to the re-designed Corvette first introduced in 1978. Previously optional equipment, including: tilt-telescopic steering columns, air conditioning, and power windows became standard equipment in 1979, though a few of the early 1979 Corvettes were produced before the decision was made to make these “optional” components standard.

The “fastback” design carried over into the 1979 model year with a few (mostly subtle) refinements made to the car’s overall appearance. For one, the “25th Anniversary” emblems were replaced by the traditional “crossed flags” which had been a key identifier of the Chevy Corvette for more than a quarter century. Additionally, the chrome trim that wrapped the 1978 rear window and the roof panels was replaced with black trim moldings. Tungsten-halogen headlights were phased into 1979 production early in the model year for increased visibility. The tungsten-halogen headlight beams replaced only the high-beam units. Lastly, a couple of carryover items from the 1978 Pace Car Package became options for the 1979 model year. These included the tinted roof panels (RPO CC1) as well as the front and rear spoilers (RPO D80). The spoilers were functional, decreasing drag by about 15% and increasing fuel economy by about a half-mile per gallon.

Moving inward, the interior received slightly more refinement than the exterior. The biggest, most notable change centered around the introduction of the new “high back” seat style previously introduced on the 1978 Pace Car Replicas. These same seats were now standard equipment for the 1979 model year. The seats used an extensive amount of plastic in their frame structure which resulted in an overall weight reduction of about twelve pounds per seat. At the same time, the new seats offered improved side bolster support to its occupants. They also featured seat backs that folded at a higher point (than most conventional seats) to permit easier rear storage area access.

The ignition cylinder lock received additional shielding to reinforce it. The previously optional AM-FM radio became standard equipment, while an illuminated visor-mirror combination for the passenger sunvisor became an available option on the 1979 Corvette. An 85 miles-per-hour (max.) speedometer, which would be officially introduced as standard equipment in the 1980 Corvette, was installed on some late-production 1979 models. This last was the result of a Federal mandate that was slated to begin in September, 1979 and would remain in effect until March, 1982.

Mechanically, both the base L48 and optional L82 engines received a 5 horsepower increase due to a new “open flow” muffler design. Additionally, the low restriction, dual snorkel air intake that had been introduced on the L82 engine was added to the L48 engine, which gave the base engine an additional 5 horsepower boost, resulting in an overall output of 195hp for the L48 and 225hp for the optional L82 engines, respectively.

In total, Chevrolet manufactured 53,807 Corvettes in 1979, which set the record for the most Corvettes built in a single year of the car’s 26 year history (and a record which still stands today!)

1980-1982

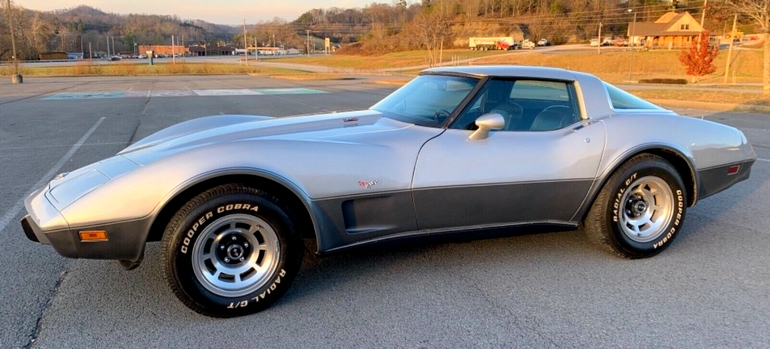

By 1980, the Corvette community was clamoring for a new Corvette. Recognizing that the current car, despite its re-design in 1978, had been around for twelve years already, Chevrolet had already begun investing into the design of a next-generation (the eventual C4 Corvette), leaving production of the current-generation Corvette devoid of significant changes for the duration of its run. Although the 1980 to 1982 Corvettes would prove to be the “swan song” of this generation, these late model cars proved that even with a new Corvette in the works, the C3 would not go quietly into the night. From revised front and rear styling elements that included integrated spoilers and fender vents with black grilles, GM was able to integrate federally required bumper standards without screwing up the look of the car. Unfortunately, dramatic declines in horsepower caused many to have a negative stigma about these last of the C3 Corvettes. However, these last years of the third-generation Corvette have also proved to be some of the most affordable Corvettes on the market today – and with a little ingenuity (perhaps replacing the factory engine with an LS crate motor, for example) – they can be made into something that rivals any other Corvette on the open road at a fraction of the cost of the newer models.

1980 Corvette

The 1980 Corvette arrived on the heels of the most successful sales year in the history of the brand. While GM engineers were already working on development of the C4 Corvette, the overall sales success of the car continued to motivate the car’s engineers and designers to further refine the aging vehicle. For 1980, several refinements were introduced to the car, though many of them were only visible to the trained eye of someone who knew the mechanics of these cars.

To start, the differential housing and front-frame cross-member were switched from steel to aluminum. Similarly, the aluminum intake manifold that had been previously used on the optional L82 engine was now included on the base L48 engine as well. Externally, engineers reduced the car’s gross weight by using lower density roof panels and by reducing the material thickness of the hood and outer door skins. Lastly, greater use was made of plastics throughout the car on everything from interior trim components to sub-assemblies in seats, and so on.

The previously optional front and rear spoilers were reshaped and made an integral part of the bodywork. Additionally, the front grilled was raked back slightly. Exterior chrome was kept to a minimum, which meant the elimination of the crossed-flag emblems from the front fenders. The Corvette emblem itself was modified some, and now featured a new, more elongated design. Additionally, the hood featured a lower profile, and new cornering and taillights were introduced. Urethane was applied during the molding of the body panels forward of the firewall and was also applied to the roof panels. This application resulted in improved surface quality, which also helped in the reduction of drag.

Mechanically, the 1980 Corvette suffered some because of increasingly stringent emissions regulations. The base L48 engine, which had been rated at 195 horsepower in 1979, lost five bhp as a result of emissions tuning – taking it back to 190HP at 4,400rpm and 280lbs/ft. of torque at 2,400rpm. Worse was the impact that California emission standards had on the Corvette. For the 1980 model, California consumers were forced to settle for a 305 cubic inch engine – the same used in Chevrolet’s standard passenger car models. The California version of this engine came equipped with stainless-steel tubular exhaust headers, a computer command control system that adjusted air-fuel mixture and ignition timing on demand, and an oxygen sensor in a closed loop system.

Inwardly, a number of other changes were implemented, many of which were the result of either Federal requirements or the need to make cosmetic changes as a result of functional improvement. The speedometers of all 1980 Corvettes now showed a maximum speed of just 85 miles per hour. The rear storage compartments were changed from a three-lid to a two-lid design in 1980. The battery remained in a separate compartment behind the driver, but the center and passenger-side compartments were combined and were now accessible through just a single door. Additionally, power windows, air conditioning and tilt/telescopic steering were made standard options, a new ribbed-pattern cloth interior was introduced, a side-shield was added to the driver side sunvisor to reduce sun glare, and the power door lock buttons were relocated to increase operator convenience. Lastly, a new convenience group was developed that included time-delayed dome and courtesy light operation, a headlight warning buzzer that signaled when the headlights were still on after the vehicle was shut off, a low-fuel warning light, intermittent windshield wipers, and a passenger-side illuminated visor mirror.

Chevrolet sold 40,614 Corvettes in 1980, which was roughly a 20 percent decline in sales from the 1979 model year.

1981 Corvette

On June 1, 1981, production of the Corvette began its transition from eastern Missouri to southern Kentucky as the first Corvette was completed at the new Bowling Green Corvette plant. Because of the decision to move production from Missouri to Kentucky, Chevrolet revised the Corvette engine program to include just a single engine for the 1981 – the L81 small-block 350 cubic inch V-8 engine. The engine, which was rated at 190 brake horsepower at 4,000rpm and 280 lbs/ft peak torque at just 1,600rpm, featured an auxiliary electric cooling fan that worked in conjunction with a smaller, engine driven cooling fan, which aided in the reduction of noise.

The 1981 model year was the first since Corvette’s earliest days to offer a single engine option for all models – including Corvettes built for sale in California. Making the L81 engine legal for use in California was simply a matter of incorporating the lightweight tube headers (with oxygen-sensor smog controls) and computer controls used by the LG4 V-8 in 1980. What was even more significant for California consumers was that the L81 could be mated to a four-speed manual transmission, meaning that manual-trans Corvettes could be sold in that state for the first time since 1975. This is also ironic because the 1981 Corvette was the last third-generation model to be offered with a manual transmission.

The most significant improvement to the 1981 Corvette over earlier models was the introduction of Computer Command Control (CCC).

A few weight savings measures were introduced to further help with the improvement of gas mileage. The aforementioned magnesium valve covers used on the L81 were actually incorporated as a weight savings measure. Additionally, Chevrolet introduced a mono-leaf fiberglass rear spring. Added to automatic-transmission Corvettes with standard suspensions, this plastic spring weighed only 8 pounds, compared to the 44-pound steel leaf springs used in 1980.

Inwardly, the dashboard in the 1981 Corvette received a more modern and user-friendly makeover, including the introduction of a standard quartz clock and electronic tuning for all factory radios. A new six-way power driver’s seat was also introduced (one which finally reclined (a notable shortcoming of the seats in earlier third-generation Corvettes).

Outwardly, the car remained virtually identical as it had in 1980, with the exception of a new paint option – RPO D84 – that was offered exclusively for the 1981 Corvette. As Chevrolet officials were extremely proud of their new paint processes at the Bowling Green manufacturing plant, they chose to showcase them by featuring a two-tone paint option on almost all of the cars built that first year. Four two-tone combinations were offered – Beige/Dark Red, Silver/Dark Blue, Silver/Charcoal, and Autumn Red/Dark Claret – with sales of those combinations totaling 5,352 units

Of the 40,606 Corvettes built for the 1981 model year, 8,995 were manufactured in Bowling Green, Kentucky.

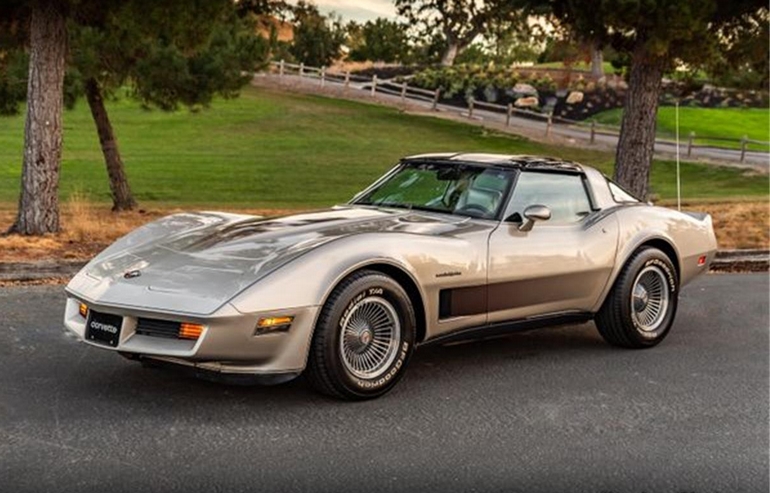

1982 Corvette

It could be argued that the 1982 Corvette was as much a test-bed for the technology being developed for the fourth-generation Corvette as it was the outgoing model of the current third-generation Corvette. Afterall, the 1982 Corvette was fitted with the same, revised engine and transmission which had been developed for the new C4 Corvette.

The new engine was essentially the time-proven 350 cubic-inch V-8 equipped with a newly developed twin throttle-body fuel-injection system instead of a carburetor. Improved Computer Command Control (CCC) electronics governed the duration of injector opening in response to signals from various engine-mounted sensors. The new CCC was capable of making eighty adjustments per second (compared to just ten adjustments per second on earlier versions of the system). The fuel delivery system was given the name “Cross Fire Injection.” The “Cross Fire” 350 was given the engine designation L83, and was rated at a respectable 200 bhp at 4,800 rpm, which was a 10 horsepower increase over the 1981 Corvette’s L81 engine.

Like the engine, the 1982 Corvette came equipped with only a single transmission – a four-speed automatic transmission designated the 700-R4. Essentially a variation of the Turbo Hydra-Matic, the 700-R4 included a long-striding overdrive fourth gear. The transmission was electronically linked to the car’s ECM (Engine Control Module.) The ECM controlled shifting and made adjustments based on speed and load data inputs. No manual transmission option was offered in 1982.

Other notable mechanical refinements to the 1982 Corvette included an in-tank fuel pump and a new fuel metering system which included a positive fuel cutoff to prevent engine run-on (dieseling.) A new solenoid-operated trap door was installed in the hood that opened at full throttle to allowed the engine to “breathe” better. The charcoal air filtering element of the 1981 model was replaced with a paper element. The exhaust system was extensively redesigned around a significantly smaller and lighter catalytic converter.

Outwardly, the base coupe model received few cosmetic alterations. The most notable outward changes were the addition of “Cross Fire Injection” labels above the front fender vents and a two-tone paint option – silver over a deep burgundy – that was reminiscent of the 1978 Pace Car Replica models (those these earlier cars were actually painted silver and black.)

Inwardly, there were a few minor, but identifiable, additions/changes made to the 1982 Corvette. The most notable of these (remember, we said MINOR details) was the introduction of a new, console mounted, quartz clock. The identifier of these clocks was simply that the clock’s face had the word “QUARTZ” printed on it. A small detail to be sure, it nonetheless is a unique identified of the 1982 Corvette.

To celebrate the C3’s departure, Chevrolet introduced a commemorative “Collectors Edition” model in 1982. The 1982 Collectors Edition Corvette introduced a frameless lifting rear-glass hatchback in place of the fixed rear glass window assembly. The car was finished in a special silver-beige metallic paint with a graduated shadow-like contrast striping on the hood, fenders and doors. It featured special bronze-tinted T-tops and special finned “turbine” alloy wheels like the ones first introduced on the 1963 Split-Window Corvette Stingray. Each of the 1982 Collector Edition Corvettes were affixed with a unique vehicle identification plate to deter individuals from cloning their base model Corvettes to look like a Collector’s Edition model (an issue that continues to plague the 1978 Corvette Indy Pace Car model to this day.)

The interior of the 1982 Collectors Edition Corvette featured a silver-beige leather upholstery and door trim that matched the car’s exterior paint color. In addition to the leather upholstery, the steering wheel also received a matching hand-sewn leather wrap including the horn cap.

Final sales numbers of the 1982 Corvette included 18,648 base coupes and 6,759 Collectors Edition hatchback Corvettes.

The C3 Corvette Buyers Guide

Know What To Look For Before You Begin Looking

When shopping for a C3 Corvette, it is important to remember that you are looking at a used car that has been around for decades. Because of this, you’ll definitely want to maintain a little more discretion when considering a potential purchase. Many Corvette owners take great pride in the proper care and maintenance of their cars, but that doesn’t mean the car is devoid of potentially costly issues. The old adage of “what you see is what you get” doesn’t necessarily apply here. There are a lot of potential issues that may not be immediately visible when looking over a used Corvette. Even if the car looks like it belongs on a showroom floor, remember to be thorough and to take your time – go over every facet of the car. While there are MANY amazing third-generation Corvettes out there – you don’t want to get stuck with someone else’s problems.

NOTE: While this C3 Corvette Buyers Guide is intended to help you make a well-informed decision, we always encourage you to seek the advice of an expert.

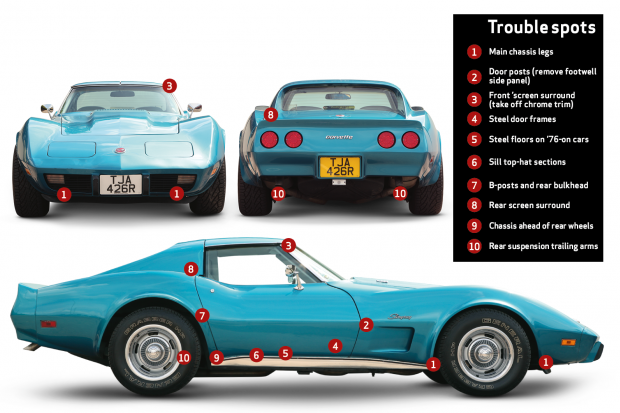

FRAME RUST / BIRDCAGE RUST

One of the “unseen” problems with a car that includes a fiberglass body is that they don’t rust – on the surface. Why is this a problem? Because the outward appearance of the car may not represent what’s going on inside/beneath the surface. Just because Corvette bodies don’t rust doesn’t mean that their frames won’t. The steelwork on these cars is extensive and is definitely rust prone, especially on cars from northern climates that may have been exposed to years of salt on icy roadways or cars from areas near the ocean where airborne salt water may have accelerated the corrosion process.

When evaluating a C3 Corvette, start with an inspection of the undercarriage. Have the car put on a lift so that a thorough examination of the undercarriage can be completed. Remove trim panels where possible and look for potential damage and for frame integrity. Inspect the chassis, the door frames and the “birdcage” – the area that links the sills, door posts, screens and roof bridge assembly. Make sure to take the time to examine each piece closely, looking for rust debris, fatigue around weld points and overall structural rigidity of the steel itself. On cars equipped with T-tops, look at the center bar that replaces the cross braces at the windows.

Make sure to inspect the trailing arms. They can gather dirt and debris and are prone to rust. Additionally, take the time to perform a visual inspection of the internal side of the body panels as well. Make sure each panel is properly mated to the other, that each sits square and appear to be bonded properly to its appropriate sub-structures. Ensure that all sub-structure assemblies appear to be in good condition, especially at the bottom of the windshield posts, the radiator support and front body and bumper-support structures.

The chassis is also vulnerable to corrosion, especially in the boxed side rails beneath and behind the doors.

BONDING STRIPS

The C3 Corvette’s body was made up of approximately two dozen separate body panels that were glued together using a unique bonding adhesive and bonding strips. The bonding strips are thin sections of fiberglass glued to the reverse sides of abutting panels.

Take time to examine the bonding strips and the body panels. Make special note of any body panels that appear to be smoother or have a different bonding arrangement that other panels on the car. These can be indicators that a body panel has been repaired or replaced. While not necessarily a deal breaker, it will help identify areas that have been previously damaged and, more importantly, help determine if they were repaired correctly.

ALIGNMENT OF DOORS, HOOD, TRUNK AND BUMPERS / STRESS CRACKS

Along with evaluating the body panels and bonding strips, take time to look for uneven gaps in the body panels, bumpers that appear to be misaligned and/or mismatched paint. Look for doors that are difficult to close or doors that “don’t line up” (as in the example above.) While there may be a reasonable explanation for these gaps, all of these items could also be indicators that the car was previously damaged – either as the result of an accident or improper maintenance. Additionally, look for crazing, stars, ripples and cracks in the body panels and in the wheel arches. Commonly known as “stress cracks”, these are all indicators of paint shrinkage and can result in expensive body work/repairs.

RUBBER BUMPERS

All C3 Corvettes manufactured from 1973 to 1982 utilized plastic bumper/fascia assemblies. While this type of assembly is commonplace today, it was in its infancy when introduced on the third-generation Corvettes. As a result, the materials used on these cars was considerably less durable, and many of these assemblies are known to crack, become brittle and deteriorate over the course of time. Fortunately, these fascia/bumper assemblies are available from many aftermarket manufacturers, but it is important to remember that they can be costly to repair as they are labor intensive to have properly fitted, bonded and painted to match the existing body color.

T-TOP ISSUES

Anyone that has ever owned a vehicle equipped with T-Tops know of the many potential issues they can cause. From noisy air gaps to squeaks and rattles to water leakage, poorly maintained T-Tops can be the cause of a lot of trouble. They can also be expensive to properly repair.

Inspect each T-top thoroughly. Test the operation of the latches on each unit. They should be tight without being difficult to lock/unlock. Remove the T-top from the car and evaluate the condition of the weatherstripping on each assembly. If the weatherstripping is cracked or dry-rotted, it will need to be replaced. Look at the glass in each T-Top as well. Make sure it is devoid of cracks, crazing or other damage that could indicate that the T-Top has been compromised in some way. Keep in mind that T-Tops on later models are more prone to cracking (due to the use of thinner glass on these units.)

HEADLIGHT ASSEMBLIES

Although the tuck-away headlight assemblies found on all of the third-generation Corvettes definitely add to the mystique of the car, it is important to take time to inspect the operation of these units carefully. The C3 Corvette utilized vacuum operated headlight doors throughout its production run. On early models, the windshield wiper cover was operated using the same technology. Because vacuum lines are made of rubber and are exposed to engine heat during operation, they are prone to become brittle and cracking, which can result in vacuum leaks (and other issues.) A visual inspection of the vacuum lines is important not only for the headlight assemblies, but as a measurement of the car’s care and maintenance. When operating properly, the headlights should open simultaneously and without hesitation.

DISC BRAKES

The third-generation Corvette had disc brakes on all four wheels. However, these brakes were largely a carry-over of the same brake system first introduced on the C2 Corvette and were known to corrode over time, causing brake failure during vehicle operation. While aftermarket brake assemblies have since been developed to overcome/resolve this issue, it is important to evaluate the condition of the existing brake system on the car prior to purchase.

You should inspect the fluid level in the master cylinder reservoir and examine the fluid color. Check the rubber bladder beneath the master cylinder cover and verify that it is not swollen or corroded – this could indicate contamination of the brake fluid. Look at the brake lines and calipers and verify that the lines are free of corrosion. Look for dripped/leaking brake fluid. Verify that the brake pedal is firm and not spongy.

INDEPENDENT REAR SUSPENSION

The third-generation Corvette continued to utilize the independent rear suspension system previously used on the C2 Corvette. The rear suspension on these cars is subject to a number of maintenance issues. When inspecting the car, make sure to check the U-joints, half-shafts and trailing arms to ensure that all components are tight and free from corrosion. If any of these components is fatigued, they will need to be replaced prior to operating the car for any length of time. Make sure that components that require lubrication have been properly maintained and look for leaks, rust or other signs of deterioration.

INTERIOR

While not critical to vehicle operation, the condition of a car’s interior says a lot about the level of care given to the rest of the car. The driver and passenger seats (made of vinyl or leather, depending on the year), are known to wear, especially on the side bolsters. The center consoles and the dashboard are both prone to cracking, especially from daily prolonged exposure to sunlight or extreme fluctuations in temperature. Inspecting these elements will provide an indication of how and where the car was stored as well as how it was operated.

In addition to the dashboard and seats, take time to inspect the carpets for moisture. Damp carpets is a strong indicator of corrosion/rust in the floorpans and should be a definite warning sign of bigger, unseen issues. Similarly, inspect the headliner, especially on cars equipped with T-tops, for moisture and/or water stains.

What To Look For Once You Start the Shopping Process

MAKE SURE THE CAR IS COMPLETE AND ORIGINAL AS POSSIBLE

When looking at any C3 Corvette, an important item to identify is whether the car in question is “numbers-matching.” A numbers matching car is any car whose VIN, engine serial number, transmission serial number and rear axle serial numbers all match. Number Matching actually emerged as the result of the NCRS (National Corvette Restorers Society) establishing a standard that could be used to measure the originality of any car. Today, number matching cars tend to be more valuable (by as much as 30%) than a car that has been modified, even if said modifications improved the performance and/or handling of the original car.

While numbers matching cars are definitely desirable among collectors, finding a used C3 Corvette that has aftermarket components (engines, transmissions, etc.) does not necessarily indicate a problem with the car. It is important to ask the current owner for the history on any modifications to the car – as much to know what components have been installed as to ensure that the changes made were properly installed and operating as intended.

If number matching is important to you, take the time to verify the VIN (Vehicle Identification Number) and engine casting numbers to ensure that the components included with the car in-question are original. Corvsport.com has a complete list of all the vehicle identification numbers, engine casting numbers, etc., for each model year of Corvette produced.

One item that tends to cause issue/concern among Corvette enthusiasts is coming across a Corvette that has been re-painted a different color. Once again, this is not necessarily a deal breaker, but color change on a Corvette is a major detractor from the standpoint of re-sale, so it should be taken into consideration prior to purchase.

GET A USED CAR CHECK

Take time to have the car checked by a reputable mechanic (either at a dealership or trusted service garage). Ask them to check the vehicle’s fluids, perform a compression test on each of the cylinders, check the brakes, the steering linkage, the cooling and electrical systems and the safety restraint/airbag systems to ensure that everything on the car is as it should be. While you’ll probably have already inspected a number of these items yourself, having a trained professional verify your findings will provide you with a greater peace of mind before handing over your hard-earned dollars for a used sports car – even one as nice as a Corvette!

TEST DRIVE

After you’ve done all of your homework, its time to get your prospective Corvette out on the open road. The test drive will allow you to experience the car in a way that no inspection ever could. It will help you determine whether or not the car is a good fit for you as a driver. Even a perfectly maintained Corvette isn’t going to be of value (or enjoyment) to you if you aren’t comfortable driving it. For some prospective owners, a C3 Corvette might sit too-low-to-the-ground, or the cockpit might seem too compact (keep in mind these cars are all two-seat sports car with no backseat and limited storage space, especially in the convertible models.) For others, the ride may be too harsh, or the exhaust and/or road noise might be too loud.

It is important to remember that the C3 Corvette evolved considerably from its introduction in 1968 to the end of its production in 1982. As previously stated, the suspension was refined throughout the car’s lifespan as was its creature comforts. We recommend you drive several different examples – while they’re all based on the same platform, you’ll be surprised how different each year is from the others.

Also, the test drive is another means of checking the car’s operability. When driving the car, don’t allow the passenger (which will probably be the car’s current owner) spend the entire drive talking at you or with you. It is important that you listen to the car. Pay attention to any clunks, engine or transmission noises. Also, take enough time to really put the car thru its paces. Observe if the car wants to pull to the left or right. Be intentional about testing the brakes and the steering. If it is a manual transmission, pay attention to when the clutch begins to catch – if it’s got a high clutch pedal, it could indicate that the clutch is worn out. Look for smoke coming from the exhaust or beneath the hood and pay attention for any unusual smells – such as burning oil or engine coolant.

TAKE YOUR TIME

For most of us, buying a Corvette is an emotional experience. It’s a promise that many of us make to ourselves when we see our first Corvette that “someday I’m going to have one of my own.”

If you are in the market to buy your first (or next) Corvette – CONGRATULATIONS! This is an exciting time for you, and it is understandable that you’d want to find the “perfect” car to bring home and have for evermore. However, you must practice patience when shopping for a used Corvette. Just as you dream of drifting thru the corners and tearing up the straightaways at (insert favorite local race track here), the people who purchased the cars you are now looking at dreamed the same dreams. As such, finding the right Corvette is a little different than buying a “daily driver” that you’d use for your commute back and forth to work. These cars are driven harder, faster and often with less regard to the wear and tear than to the exhilarating experience of flying thru a sharp turn just a little too fast.

Because of this, you’ll want to follow all the steps we outlined in this article. You’ll want to keep emotion out of the decision making process as much as is humanly possible. That’s not to say you shouldn’t enjoy the experience, but be informed and purchase a Corvette that passes all these search criteria so you’ll have as much enjoyment with your Corvette after you make the purchase as you did finding it in the first place. It is also worth noting that shopping for a Corvette can be a lot of fun! You’ll definitely get to drive some amazing cars along the way…and here’s where you should embrace and enjoy the journey of finding the “perfect Corvette.” If nothing else, you can be certain that when you do finally make your big purchase, you’ll have found a Corvette that is perfect for YOU.

ANTICIPATE OWNERSHIP COSTS

There is one other item worth considering when purchasing a 40-year old Corvette. This car is likely not going to be your primary means of transportation and, as such, this car will not be driven daily. Make sure you’ve got sufficient space to store your automobile. Additionally, you’ll want to contact your insurance provider to determine the cost of insuring a Corvette. Keep in mind that the amount of anticipated mileage to be driven each year will influence the cost of insuring the car. Lastly, remember that even the best-maintained Corvettes will require some amount of maintenance, so evaluate the costs associated with vehicle maintenance and verify the affordability of the car before committing to its purchase.

What Are These Cars Worth?

The used collector’s car market is a difficult thing to measure in terms of vehicle values. Every sports car on the market today will have significant swings in its market value based on a number of varying factors including: long-term reliability, availability and demand of next-generation models (this one has a huge impact on Corvettes of all generations), rarity of particular options within a particular series of cars (such as paint color/interior color combinations, included options, limited edition models, etc.)

When trying to valuate what a used Corvette’s “worth” is, there are a number of approaches that can be taken. Fortunately, the internet has taken some of the mystery out of the valuation process because it allows would-be consumers the opportunity to look at cars across the nation (and even around the world) and compare prices in real time. It is a worthwhile exercise to get online and spend time shopping at reputable automotive websites such as AutoTrader, CarGurus, Craigslist and the like. These websites will allow you to narrow down your search to a specific model, geographic area or even by specific options that are important to you as a consumer, and the compare hundreds of similarly equipped cars that are all prospective options for purchase.

Having said all that, we’ve provided you an estimated range of what used C3 Corvettes are selling for in today’s market. Please take note that these price ranges are accurate as of Q4, 2019, and that they reflect actual market price range based on collected data from a reputable used car website. We based our search criteria on availability across the United States as well as limiting our search to a Corvette equipped with less than 75,000 miles, an automatic transmission, and standard options.

- 1968 Corvette – $18,500 – $75,900.00

- 1969 Corvette – $19,500 – $108,995.00

- 1970 Corvette – $19,500 – $49,900.00

- 1971 Corvette – $14,000 – $49,950.00

- 1972 Corvette – $16,995 – $68,995.00

- 1973 Corvette – $14,900 – $38,995.00

- 1974 Corvette – $12,950 – $44,995.00

- 1975 Corvette – $12,475 – $29,997.00

- 1976 Corvette – $10,000 – $34,995.00

- 1977 Corvette – $8,995 – $14,995.00

- 1978 Corvette – $6,900 – $49,990.00

- 1979 Corvette – $9,900 – $27,900.00

- 1980 Corvette – $7,995 – $27,900.00

- 1981 Corvette – $6,995 – $24,850.00

- 1982 Corvette – $7,995 – $27,499.00

Good Luck and Happy Hunting!

We hope this buyer’s guide helps you navigate the exciting (and sometimes challenging) prospect of purchasing a used C3 Corvette. While we’ve identified a number of items to watch out for, we also want to make sure to remind you that all of the items listed in this buyer’s guide are based on individual issues experienced at different times by Corvette owners over the course of many years. While there’s probably that “basket case” Corvette out there that is plagued with multiple issues, most Corvettes (especially those that have been maintained) will provide their owner with many happy years of fun on the open road. Additionally, it is important to recognize that any car which maintains its value (as listed above) this many years after being sold as new is most definitely a worthwhile investment.

Remember, half the fun is the experience of hunting for the perfect Corvette. We wish you every success in your search and hope you’ll drop us a line at Corvsport.com after you purchase your C3 Corvette. Good luck and happy hunting!