Today we get into some fun stuff with the eye candy, as Scot mocks up the engine and transmission, hoping to make this ’75 Greenwood Widebody a contender in the Pro Touring race series. This part seems a lot more straightforward than some of the chassis work, and Scot mentions he’ll just have to make a trans mount and engine ties back to the frame for support. And in case you missed the previous installments or need a refresher, click here for Part One, Part Two, Part Three, and Part Four.

While this looks fairly simple, Scot comments, “still have to do a lot of measuring to make sure the motor fits in the engine compartment where I want it. The shifter needs to be in the correct place.” In the meantime, he test fits the headers.

Beautiful eye candy Scot, I can already hear it rumbling in my head! Now back to some fabrication and getting the front cross ties bolted in.

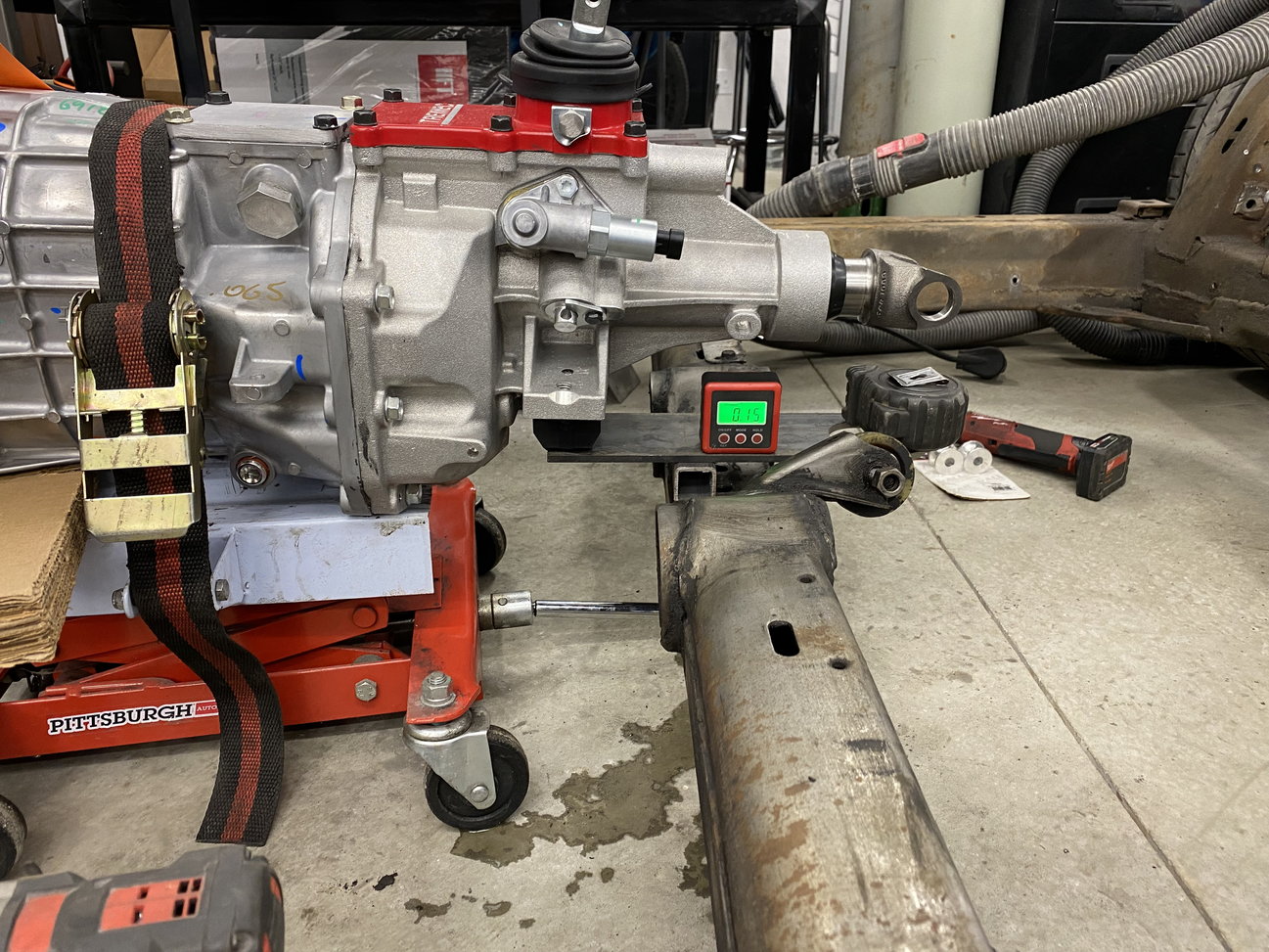

Such precision and patience are required, and here Scot mentions, “started working on trans support bracket… I may have some room to lower the engine 1 1/2 inches”. Well, that’s good news, keep that weight as low as you can!

Scot ended up being able to drop the engine by almost two inches! He also got the trans mount made and moved the differential back by a half inch.

We’ll finish up today’s installment with that beautiful widebody being lowered down on the mocked-up chassis. Scot mentions he needed to cut three compartments behind the seats to get the body dropped all the way down.

Scot’s parting words speak more to the precision and patience required for a job like this: “One of those days when my thoughts did not go as planned. Got the seats out and some of the carpet. Removed the 3-compartment trim and lids. Cut the tray’s out and started fitting the body on the frame. Got the body down on the car. Had to change a few things with the rear suspension to get it to fit, but nothing major. Now that I know it fits I can tear it all apart sandblast the frame and finish the welding.”

See you next week for Part Six! We often have vibrant discussions over on our Facebook page, I would love to hear your thoughts. Douglas B.